Contents

What you should know about SLS and HP MultiJet Fusion

Some time ago we reported here about the MultiJet Fusion process specially developed by HP and its special features.

Since this technology has only been available on the market for a little over a year (May 2016) and therefore still has comparatively little experience, we would like to spread HP MultiJet Fusion Printing today with what is probably the most widespread 3D printing process, selective laser sintering .

The most important thing in common

Since both 3D printing processes primarily process polyamide (=PA) plastic, it makes sense in this case to compare these two technologies side by side.

First of all, let’s take a closer look at how both methods work.

Selective laser sintering/SLS printing

Selective laser sintering is based on the local fusing of individual powder layers using a laser beam. This precisely follows the outlines constructed in the 3D files and selectively fuses the material. In this way, a break-proof 3D model is created layer by layer.

HP MultiJet Fusion printing

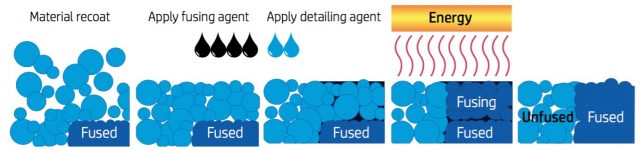

This process does not require a laser, but basically works in a similar way to (2D) inkjet printing, namely by printing in a powder bed using an inkjet print head and 2 special binder liquids. It is crucial that it is a thermally conductive liquid that acts as a thermal inhibitor. The heat conductor now binds the actual object, the inhibitor is applied to its edges. In the following work step, infrared energy sources fuse the respective layer above the printing bed.

HP MultiJet Fusion Printing Diagram; Source: ©HP

SLS vs. HP MultiJet Fusion – similarities and differences

In addition to the PA as the printing material, both processes have in common that, unlike the FDM process, no supporting structure (also referred to as support) is required to build the object.

Compared to SLS printing, HP MultiJet Fusion uses significantly less heat, with the result that the parts take significantly less time to cool down after the printing process. In addition, MultiJet-Fusion enables a much higher level of detail and also enables even lower wall thicknesses (80µm, compared to 100µm in the SLS process).

On the other hand, SLS printing offers a wider choice of materials, colors and post-treatments, while HP Multijet Fusion is only possible with PA12 so far.

Would you like to learn more about 3D printing technologies and materials? Visit our website or contact our customer service. We would also be happy to produce sample components for you using SLS and HP MultiJet Fusion technology.

Image source: © HP

To the website