Contents

How do you make and show the cosmetic thread in SolidWorks sheet drawing?

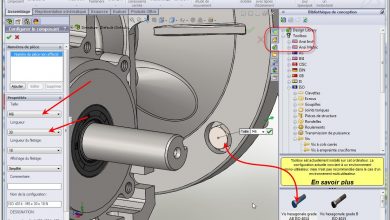

To insert cosmetic threads from assembly documents into drawings, click Insert > Model Items and click Cosmetic thread . In drawings, Insert Callout appears in the shortcut menu.

How do you add custom cosmetic threads in SolidWorks?

If the feature is a conical boss, select the minor diameter. You can also select the feature after you click the tool. (Annotation toolbar), or click Insert > Annotations > Cosmetic Thread. Set the properties in the Cosmetic Thread PropertyManager .

How do you add threads to a callout in Solidworks?

The thread callout is defined in the Cosmetic Thread feature of the source part or assembly. You use the Smart Dimension tool to add the callout in a side view or section view of the external thread. To add the callout: Click Smart Dimension (Dimensions/Relations toolbar) or Tools > Dimensions > Smart.

How do you hide cosmetic threads in Solidworks drawings?

First ensure that the Cosmetic Threads are visible in the Part environment as per the section above. Then within the Assembly environment, go to View > Hide/Show and ensure that ‘Hide All Types’ is deselected and ‘Component Annotations’ is selected.

What are cosmetic threads?

A thread lift is a type of procedure wherein temporary sutures are used to produce a subtle but visible “lift” in the skin. Instead of removing the patient’s loose facial skin surgically, the cosmetic surgeon simply suspends it by stitching up portions of it.

How do I show thread lines in Solidworks drawing?

SOLIDWORKS allows you to specify the quality of threads displayed in a given view. To find this option, select a view and scroll down in the property manager on the left. at the bottom of the panel you will find the option to set your Cosmetic Thread Display to High, or Draft quality.

How deep should I thread a fastener?

The depth of a fastener should be at least two times its nominal diameter. For example a 1/4in (0.25in) fastener should be threaded at least 1/2in (0.50in) deep. Any deeper than this and the threads don’t really do much except add assembly time.

What does 6g mean in screws?

Screws threads with identical external tolerances and pitch tolerances are expressed with a single tolerance letter and number. For instance, a screw with a 6g major diameter tolerance and a 6g pitch diameter tolerance would simply be written as “6g”.

How do you classify a thread?

For Unified inch screw threads there are six standard classes of fit: 1B, 2B, and 3B for internal threads; and 1A, 2A, and 3A for external threads. All are considered clearance fits. That is, they assemble without interference. The higher the class number, the tighter the fit.

How do you call out metric threads?

Metric thread fits: A fit between metric threads is indicated by internal thread class fit followed by external thread tolerance class separated by a slash; e.g., M10 x 1.5-6H/6g. The class fit is specified by tolerance grade (numeral) and by tolerance position (letter).

How do you call a tapped out hole?

The tapped hole callout format is: Ø tap drill diameter + depth; thread specification + depth; quantity of holes desired (not included if only one hole is specified) Notice that when working with blind threads (i.e. not thru) you must drill an additional screw diameter (Ø 0.190″) beyond the desired thread depth.

How do I create a NPT thread in Solidworks?

Utilizing the Hole Wizard Feature Set the standard to ANSI Inch, set Type to Tapered Tap Pipe Tap and in the hole specifications, select the desired size in inches. The next step is the End Condition which defines the total length of the thread, it can be left as the default value or customized to a specific distance.

What is the difference between tapped hole and bottoming tapped hole?

the only difference what i could find is that the drill depth. Tapped hole have aproximately 2mm more drill depth when compared with bottoming tapped holes.

What is a lunchtime facelift?

Lunchtime facelift, also known as the thread lift or mini face lift, is the less invasive and cheaper alternative to the traditional facelift. The procedure entails lifting different parts of your facial skin using threads. Essentially, it involves hooking the skin and pulling it up to correct the sagging of the skin.

Are thread lifts worth it?

A liquid nonsurgical facelift costs $2,250 on average, according to RealSelf members, and lasts from six months to two years, depending on the type of filler used. Despite the temporary results, 100% of RealSelf members who reviewed this procedure say it’s “Worth It.”