Best answer for this question, how do you create gears in CAD?

- Start AutoCAD.

- Make 2 circles.

- Make the profile of the gear tooth spaces.

- Trim the circles side ways.

- Now enter “bo” command. It will show the boundary creation dialogue.

- Click inside the region and then press enter.

- Now we have the polyline created.

- Make a circle of 50mm radius.

Quick Answer, how do you draw gears?

Subsequently, how do you make worm gear in AutoCAD?

- On the ribbon, click Design tab Power Transmission panel Worm Gear .

- On the generator, Design tab: Enter the values to the Common section.

- Click OK.

You asked, how do you make 3D gear?

Contents

How do you design involute gears?

When drawing an involute, you draw one side of one tooth, mirror that to make a whole tooth, and that copy that around your gear the right number of times. A new involute has to be drawn for each size of gear in your system. To begin drawing, lay out three concentric circles: One at the pitch circle.

How are gears made?

Gears can be manufactured by a variety of processes, including casting, forging, extrusion, powder metallurgy, and blanking. Of these, machining is the most common manufacturing method used. Gear machining is further classified into two categories: gear generating and gear form-cutting.

How do you draw cogs and gears?

What are gear ratios?

A gear ratio is the ratio of the number of rotations of a driver gear to the number of rotations of a driven gear. A colon is often used to show a gear ratio: gear ratio = rotations of a driver gear : rotations of a driven gear.

Who invented worm gear?

Archimedes can quite justifiably be considered the inventor of worm gearing. His name is also applied to the thread, Archimedean Screw. (Fig. 1.1).

How do I make custom gears?

- Go to My ROBLOX.

- Go to Profile.

- Go to Stuff.

- Go to Decals.

- Click Create.

- Click Choose File.

- Select your desired photo.

- Click Create Decal.

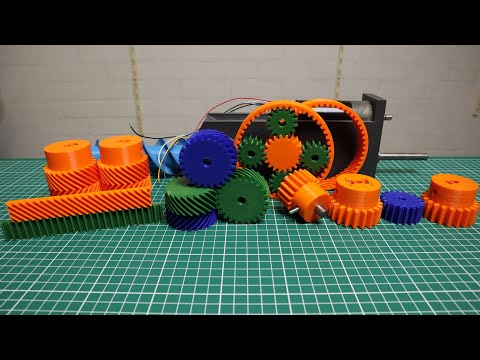

How do you make strong 3D printed gears?

To achieve more robust teeth, basically, double the width means double strength. In terms of thickness, it is recommended to design it at least 3 to 5 times the circular pitch of the gear. Keeping those values in mind should help you to produce strong 3D printed gear.

Is it possible to 3D print gears?

Although it might at first seem unintuitive, 3D printing gears is not only possible but very much worthwhile. While 3D printed gears are inherently weaker than their metallic and plastic-injected counterparts (unless you’re using a 3D printing service), they’re nonetheless suitable for a wide array of applications.

How do you make a sprocket in AutoCAD?

- Click Content tab Tools panel Chains/Belts drop-down Sprocket/Pulley.

- In the Pulleys and Sprockets dialog box, select Chain.

- Select the Library button.

- In the Select a Chain dialog box, select the type of the chain.

- In the Select Part Size dialog box, select the size of the chain.

How do you make a helical gear in AutoCAD?

- Start AutoCAD.

- Make a circle of 35mm radius at center.

- Make another circle of 50mm concentric to previous one.

- Make two arcs like this one for cutting teeth.

- Trim down the circles.

- Right click on the screen and select multiple.

- Select all arcs.