One of the highlights this week is the LaserFactory, a manufacturing solution that uses a laser cutter to construct robots, drones, and other electronic devices—all in a fully autonomous way. It’s a 4.0 manufacturing system that may also feature a 3D printer in the future. You can also marvel at Sintratec’s 3D-printed third hand and watch the latest edition of the IGO3D format “Let’s Print!”. We would also like to take the opportunity to show you a hut with 3D printed walls and a behind-the-scenes look at ARAN, who recently acquired an additive micro-manufacturing machine. We wish you all a nice Sunday.

Contents

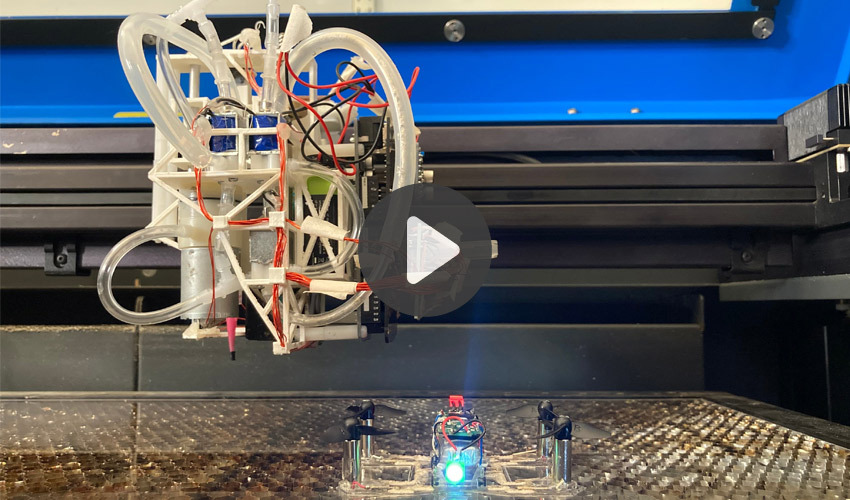

Top 1: LaserFactory, a robot creation solution

At MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL), researchers have developed the LaserFactory – a system capable of building robots and functional drones in an autonomous manner. Thanks to the laser cutter and the associated software, he is able to design electronic devices independently. For example, he can cut parts of different sizes and assemble them into the final shape. Although the system does not yet have a 3D printer integrated, we wanted to share this solution with you as it is a technology that could allow for the rapid creation of custom parts on demand. We let you see the machine in action:

Top 2: A portable third hand

The Swiss Sintratec AG, which acts as an SLS 3D printing manufacturer, has created and 3D printed a wearable third hand. This should support the 3D operator Tomy, who also designed it, in his daily production work and literally give him a hand. The part, 3D printed on the S2 system, consists of a stable PA12 wrist rest, a flexible TPE strap and various movable tool attachments, making it ideal for all types of craft work. How the creation went, you can see in the following video:

Top 3: Let’s Print! #15 by IGO3D

Also this week the reseller IGO3D provides us with a new episode of its format “Let’s Print!”. In keeping with the freezing cold weather and sometimes heavy snowfall here in Germany, Andreas Thurow, the service manager at IGO3D, shows us the 3D print of a very essential lifesaver: the ice scraper. He designed the ice scraper in Autodesk Fusion 360 and printed it with the Creality CR-10 S Pro. Mr. Thurow used PETG with a resolution of 0.2 mm and an infill of 20% as the material. It is best to watch the video yourself to better understand the 3D printing details.

Top 4: 3D printing and construction

If you follow the news about 3D printing, you probably remember this little shack made of 3D printed walls with very original tiles. The “Cabin of Curiosities” was manufactured by the company Emerging Objects in 2018 and consists of 4,500 ceramic-based 3D-printed tiles. In fact, the company claims that no two tiles are identical: they wanted to create an unprecedented aesthetic effect. In the video below you will have the opportunity to admire the house inside and out and discover all the surprises it contains.

Top 5: First 3D micro printer

Israeli company ARAN has just installed its first 3D microprinter, the Tera 250 developed by Nanofabrica. Although ARAN has mastered additive manufacturing for a long time and many machines have been in use for several years, this is the first time that the company has acquired a micro-manufacturing solution. This enables ARAN to meet the needs of the entire industry for extremely precise and innovative micro parts that cannot be produced profitably with more traditional processes such as injection molding. Discover this new collaboration in video:

Do you think that the LaserFactory can soon be combined with 3D technologies? Leave us a comment or share it with us on Facebook, Twitter, LinkedIN or Xing. Would you also like to receive a summary of the most important news in 3D printing and additive manufacturing directly and conveniently in your mailbox? Then register now for our weekly newsletter.