I find it interesting to see how fashionable 3D printing is today, even though it has been around for decades. Obviously, the price of 3D printing has been drastically reduced, which explains the huge increase in demand. 3D printing is a great way to test a product, and it’s pretty fun. Just as 3D printing has become popular on the hardware side, we are starting to see more commonly used simulation tools on the software side. Simulation tools have been around for decades as well, but previously you had to have a doctorate to be able to run the tests. Today, it is impressive how many virtual tests can be performed in SOLIDWORKS.

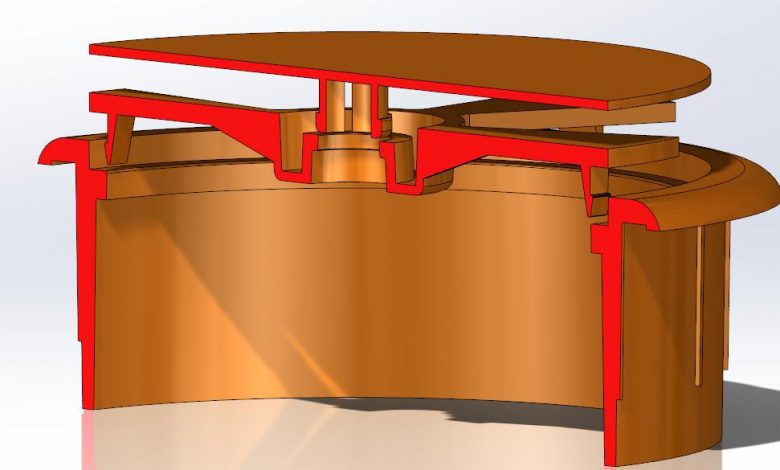

Peter Rucinski and Stephen Endersby (Product Managers at SOLIDWORKS) recently presented a 22 minute webinar (you can register to view the recording), where they took a snap-in grommet mechanism that they tested for manufacturing and for use (fit for purpose). It’s impressive how quickly you can test a part in your design software, both for fabrication and for real-world use. If you are designing parts that require rigorous quality controls to determine if they can be economically manufactured with acceptable quality and can perform under all types of working conditions, then you understand that the designs sent for manufacturing, which are not suitable for use, will result in additional costs and delays. This recorded webinar can give you a better idea of how simple this process is. Click here to register to access it.

Cliff Medling

Senior Marketing Manager – SOLIDWORKS