In 2011, one of my youthful passions came to the surface when I decided to buy a new watch. Twenty years ago I was content with ordinary watches, but now I am looking for more sophisticated watches. Very quickly, I found myself immersed in countless blogs and specialized forums, as many sources of information that did not exist or barely 20 years earlier. For four years, I didn’t settle for just one watch: I bought, sold and traded around 40 watches of all kinds.

As I explored the world of watchmaking, I began to design watches that I would like to wear, without taking the step of design. At the beginning of 2013, I stumbled upon a video explaining how Franck Muller was using SOLIDWORKS to create his watches… and that’s where it clicked. I was already familiar with SOLIDWORKS because my company used it to design electrical equipment. The seed was planted, but what could I really hope for? Not only was I not an engineer by training, but I didn’t know anything about CAD.

Towards the end of 2013, I started working for TriMech, a local SOLIDWORKS reseller on the east coast of the United States. Over the next 18 months, I crossed paths with a wide variety of companies who all used SOLIDWORKS to design and build amazing products. Over time, I got used to the idea of using SOLIDWORKS on my own. In the spring of 2015, SOLIDWORKS offered free access to a training video on the MySolidWorks portal and a coupon to take the exam of SOLIDWORKS partner certification (CSWA). Jumping at the chance I bought SOLIDWORKS Professional, took the training and got my exam.

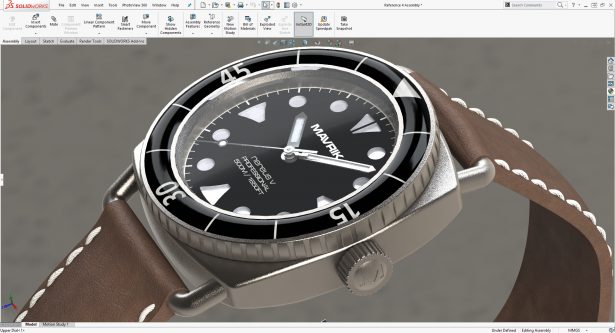

For 10 months, I worked hard on the design of my first watch. I started by disassembling dozens of watches in order to better understand the fundamentals of their manufacture. I modeled my first watch based on my own tech specs and my love of ancient monsters. Throughout the process, I posted hundreds of renderings created under Photoview 360 on Facebook, Instagram and several forums. Many enthusiasts offered me valuable advice and a collaborative process then began between the seller and potential buyers, a real “participatory design”. I made a 3D print of several versions of my watch to check that everything was perfect. I then contacted and evaluated suppliers and ordered my first prototypes. Finally, the tests made it possible to validate all the technical requirements, in particular the waterproofing at a depth of 500 m. Which brings us to the present moment.

My leap of faith undertaken in 2015 is today rewarded with the launch of Mavrik Watch Company’s very first watch, the Nereus V. This timelessly styled diver’s watch incorporates modern materials such as titanium, CuSn8 bronze and sapphire. . We are happy to announce that the Nereus V Kickstater campaign officially started last Tuesday. Come and discover our watch! Watch the Nereus V video on the Kickstarter campaign page.

After creating the Mavrik Watch Company, my choice fell on the slogan “Be Yourself. Be a Mavrik. The word Mavrik comes from “maverick”, an English term which designates a person with an independent spirit and most often unconventional. The world is a self-defining principle for us: no matter who you are or what you do, always try to be the best possible version of yourself. If you have a crazy dream, like making a watch for example, I can only encourage you to take the plunge into the unknown using tools as powerful as those in SOLIDWORKS. And never forget: “Be a Mavrik! “