Contents

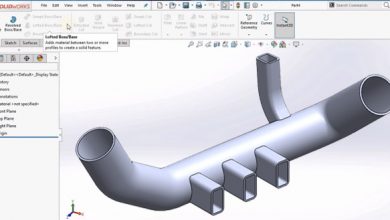

How do you draw a hollow cylinder?

Sketch a circle, with a diameter of 56 mm, on top of the cylinder. This circle will become the sides of the hollow cylinder. Select the top of the cylinder as the plane you want to sketch on. Position the cursor over the center point of the top face to use it as the origin of the sketch.

Why are hydraulic cylinders cushioned?

Why Is Cushioning Necessary? Cushioning is needed to lower the speed of the cylinder before it reaches the end cap. Lowering the speed of the piston helps reduce stress on the components within the cylinder. It also lessens vibration conveyed to the other parts of the machine.

How do you make a hydraulic cylinder go faster?

If the air problem is corrected, the system will speed up. Oil line cleared — If a restricted or blocked oil line becomes unrestricted/unblocked, the fluid flow will increase. Change in load — If the load on the cylinder is reduced, it may increase cylinder speed.

How do you make a gear design?

For design of gears, determine elements such as size, tooth shape, pitch, number of teeth, amount of profile shift, material, need for heat treating and/or grinding, choice for kind of tooth surface finish, amount of backlash, helix angle, helix direction, method of mounting on shaft, precision class, etc., the …

How do you make a hollow cylinder in Assassin’s Creed Unity?

(for free) Do make it hollow, make a cylinder, switch to edit mode, then select the circle faces, press delete, then press faces. That should hollow out the cube. Go into file, then click export, then export as OBJ. Open it in Unity, and this should work.

How do you make a hollow cone blender?

Or alternatively create a circle with an ngon face, then select all, press e to extrude it, enter to drop it where it is (without moving the mouse), then scale down to however small you want the hole in the top of the cone to be, then move those shrunken vertices up to make your cone shape.

How do I look like a cylinder?

A cylinder has two flat ends in the shape of circles. These two faces are connected by a curved face that looks like a tube. If you make a flat net for a cylinder, it looks like a rectangle with a circle attached at each end.

What is the benefit of a closed hydraulic system?

A closed loop circuit can operate smoothly in forward and reverse directions without a directional valve being involved. This eliminates the need for the valve component, which can be costly and take up valuable real estate on mobile equipment. This also cuts down on hose and fitting complexity and space.

What is the function of hydraulic cylinder?

Function of hydraulic cylinder is to provide linear motion. It converts the fluid energy into mechanical energy ( linear movement).

How does a cushioned hydraulic cylinder work?

Standard hydraulic cylinder cushioning provides a simple restriction of return flow from the cylinder during the last inch or so of stroke at either or both ends. A spear fixed to the end of the cylinder’s piston rod makes contact with a closely fitted hole in the end cap of the cylinder.

How does a hydraulic pressure intensifier work?

Hydraulic pressure intensifiers, sometimes referred to as hydraulic pressure boosters, generate a higher pressure from a low-pressure hydraulic power source. They always work powered by a pump, which is operating at a set pressure and from this the intensifier simply generates a higher output pressure.

Which of these actions does a hydraulic cylinder perform?

A hydraulic cylinder is a linear actuator converting hydraulic energy into linear motion and force.

How do you increase hydraulic power?

there is one way to increase pressure in system there is pressure relief valve in the gear pump or hydraulic pump which is operated on set pressure. when power consumption reduced pipe pressure gets increased and this valve get actuated to recirculate the fluid into the gear pump.

What determines how fast a hydraulic system moves?

There actually are three variables that affect flow: the orifice size, the pressure difference between the inlet and outlet of the orifice, and the oil temperature.

How do you control the speed of a hydraulic motor?

Its speed can be varied by adjusting the setting of the throttle of the flow control valve. The speed can be infinitely varied as the excess oil goes through the pressure relief valve. When the four-way valve is de-activated, the motor stops suddenly and gets locked.