Contents

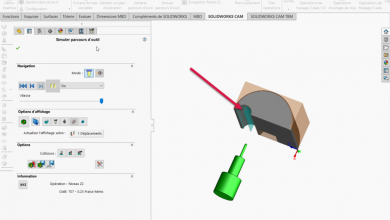

How do you open Sheet Metal in Solidworks?

To do this we simply need to right-click any tab on the CommandManager and select Sheet Metal from the drop down menu. Next, we will activate the Sheet Metal tab of the Command Manager and click Base Flange/Tab tool, which should be the first tool on the right not grayed out when beginning a part.

Does solidworks have Sheet Metal?

It’s Not Just a Metal thing! Within SOLIDWORKS there is a tool tab called ‘Sheet Metal’ that allows you to design from scratch or convert a 3D part to sheet metal and flatten your design for manufacturing.

What is K factor in sheet metal solidworks?

K-Factor is a ratio that represents the location of the neutral sheet with respect to the thickness of the sheet metal part. When you select K-Factor as the bend allowance, you can specify a K-Factor bend table. The SolidWorks application also comes with a K-Factor bend table in Microsoft Excel format.

What is K factor in sheet metal?

Y factor and K factor are defined by the location of the sheet metal material’s neutral bend line with respect to the thickness. … K factor is a ratio between the distance from the neutral bend line to the inside bend radius and the material thickness. K factor uses the formula K factor = δ/T.

How is sheet metal bending allowance calculated?

BA = [A x (π/180) (r + (K x T))]. The bend angle A in degrees, inside bend radius R in m, K-factor K for different types of materials & material thickness T in m are the key elements of this calculation.

What determines K factor?

The K-factor comes from the ratio of the neutral radius divided by the thickness of the material on prepared charts and has a value between 0.3 and 0.5.

How do you calculate K factor for flow?

The K-factor is the frequency divided by the flow rate => [1/s] / [g/s] = 1/g. Knowing the K-factor for each calibration point, the factory determines the best fitting K-factor for that particular flowmeter.

What is bend allowance in sheet metal?

Bend allowance is defined as the material required to add to the overall length of the sheet metal in order for it to get cut in the right size. Density in metals can be measured in GPa, or gigapascal. The more gigapascal in a material, the stiffer it is.

What is the sheet metal process?

Sheet metal forming is a process where pieces of sheet metal are modified to its geometry rather than removing any materials. The applied process generates a force that stresses the material to deform. This in turn gives the possibility to bend och stretch the sheet to a variety of complex shapes.

What is flat pattern in sheet metal?

Use a flat pattern, which is the shape of the sheet metal part before it is formed, to create drawings for manufacturing. Flat patterns show bend lines, bend zones, punch locations, and the shape of the entire part with all bends flattened and bend factors considered.

What do you first create in sheet metal design?

Every sheet metal design starts with the decision for a certain manufacturing shop and a specific material. Then you go on with creating a basic sheet metal part. You must first use a workplane and create the 2D geometry which defines the exact contours of the new basic sheet.

How do you calculate bend radius?

If you drew your arc from the inside of your bend, add 1/2 the tube outer diameter to get your true center-line radius. If you drew your arc from the outside (top) of your bend, subtract 1/2 of the tube outer diameter to get your true center-line radius.

What is the minimum bend radius?

The minimum bend radius refers to the lowest radius at which a cable can be bent. So a smaller bend radius means a cable is more flexible. The bend diameter is equal to twice the bend radius. The radius specifications help to protect the integrity of transmissions.

What is bend allowance formula?

This bend allowance formula is used to determine the flat pattern length when a bend is dimensioned from 1) the center of the radius, 2) a tangent point of the radius (B) or 3) the outside tangent point of the radius on an acute angle bend (C).

When the size of a sprinkler orifice gets bigger the K factor?

SPRINKLER SIZE AND RESPONSE TIME The K-factor increases as the orifice size of the sprinkler increases. The K-factor for a standard 1/2 inch sprinkler is 5.6.