I am pleased to announce that SIMULIA® Structural Simulation Engineer (SSE) is available on the market starting today! You can extend SOLIDWORKS® Simulation with a tightly integrated, cloud-based solution that lets you perform static structural, thermal, frequency, buckling, and modal dynamic response analyzes on parts and assemblies. Please contact your reseller to find out if SSE is available in your country.

Based on Dassault Systèmes’ 3DEXPERIENCE® platform, SSE speeds up the design process by running simulation calculations in the cloud or on your computer. Designed to give you the tools, data management and collaborative environment you need to drive innovation, this platform features a growing number of applications.

“Innovative companies around the world are continuously pushing the limits to accelerate time to market while improving product quality and lowering costs,” said Aaron Kelly, vice president, SOLIDWORKS Research & Development, Dassault Systèmes. & “We want advanced simulation technology to become accessible to small and medium-sized businesses, and SSE is a major step in that direction. Our customers can now easily, quickly, and confidently validate complex product designs created in SOLIDWORKS, and continue to innovate in their industry. “

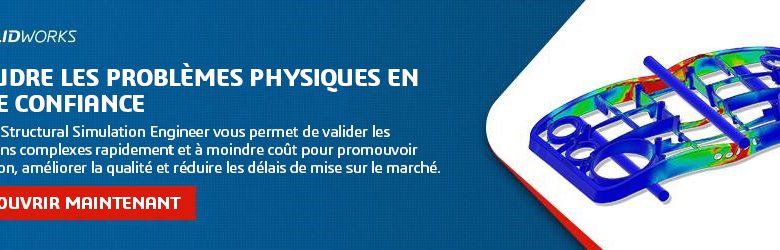

Structural Simulation Engineer provides design and simulation engineers with advanced structural and thermal simulation technology based on SIMULIA Abaqus, the proven premium FEA (Finite Element Analysis) solver. Using SSE, it is possible to quickly and reliably perform multiple nonlinear studies involving large amounts of complex friction contact materials, sequential loads, and large deformations.

SSE is directly accessible from SOLIDWORKS Simulation. You can transfer geometry and modeling features to SSE with a single click. Setting up advanced simulations takes less time by reusing loads, boundary conditions, mesh definitions, and material properties. Whenever you modify a SOLIDWORKS CAD design, the simulation model is automatically updated in SSE.

Take the example of an innovative and growing oil and gas company based in Canada. It needed more capacity to study the plastic deformation of a new drive system for a large drill motor with complex contact areas and large displacement changes. She used SSE to validate the design. Click here to read more and watch the video.

“By accelerating design and innovation, SSE has enabled us to develop breakthrough oil and gas exploration products faster and cost effectively,” explains Peter Kjellbotn, Mechanical Engineer, InFocus Energy Services. “With SSE, we were able to perform calculations locally or in the cloud with high performance resources. Resolution, which previously took place overnight, now only takes a few hours. We saved a minimum of $ 10,000 in physical testing on a single product design. “

What problems are you having with simulation? Share your comments below.

You can find out more on SSE or request a demo. If you would like to purchase the solution, please contact your dealer to find out if SSE is available in your country.