Contents

Introduction

Hello everyone,

This post aims to present two very practical tools during static Simulation calculations :

• Low stiffness

• The symmetry

For this, I will start from an extremely simple case: a 100mm diameter column with a load of 100kN on the top and simply placed on the ground (slippery ground). In theory, one should find 12.74MPa in the section.

Model 1: a complete cylinder with an embedding

One finds correct stresses, except on a zone close to the fixed support where the expansion of the cylinder is blocked by the fitting. In fact, the cylinder is placed on a slippery floor. This modeling is therefore not satisfactory.

Models 2: embedding replaced by a flat support

In this model, the embedding is replaced by a “flat support”. We must add the option “Use a low stiffness to stabilize the model” in the properties of the study.

Indeed, when one looks at the reaction forces at the level of the fixed support of model 1, one notes that one finds well the force of 100kN in the direction of the loading, but also that there is low parasitic forces in other directions.

Reaction forces in the embedded case

With the plane support, we obtain this result below.

The result is acceptable, despite a slight rigid body movement (without impact on the constraints).

Model 3: conditions of symmetry

In this model, I take advantage of two symmetries of the model + of its loadings. I only keep a quarter of the cylinder in adding conditions of symmetry at the level of the faces cut by the planes of symmetry.

WARNING : you have to think about dividing the loading by 4!

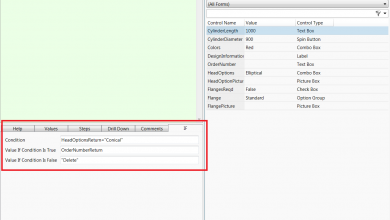

Condition of symmetry (advanced displacements)

Obtained result :

We then recover the good constraints, a correct deformation and no displacement of parasitic rigid body.

Model 4: 2d simplification

The ideal when you can, is to use an axisymmetric 2D simplification (SOLIDWORKS Simulation Professional license) to be able to mesh very finely and obtain extremely precise results.

Menus to access 2D simplification

The results obtained are with great precision.

This article is not intended to go into the details of each of these tools. However, SOLIDWORKS help is clear. We are then at your disposal for any other questions or proposals for additional blog posts.

Hope this article will help you in your work.

See you soon on the SOLIDWORKS Blog!