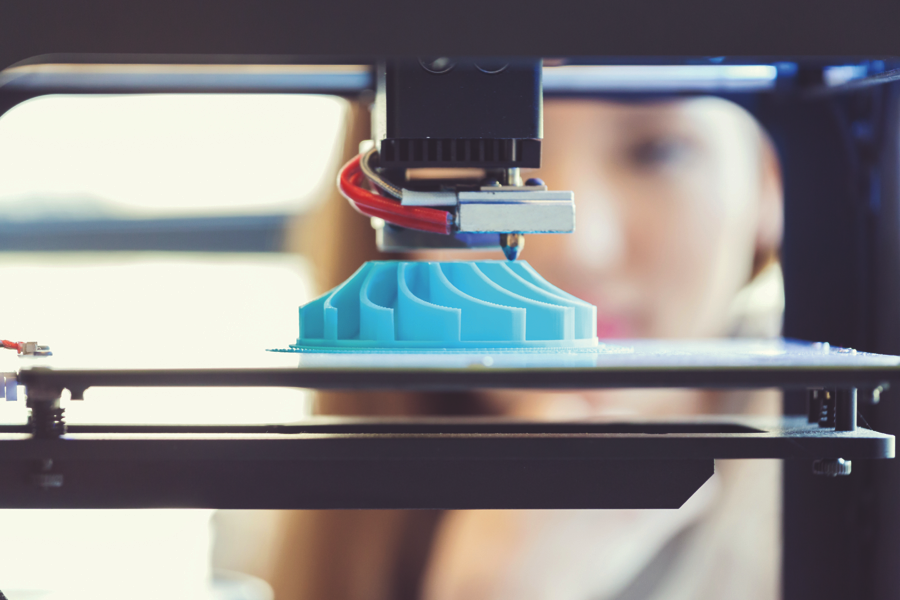

Design excellence is based on innovation, quality and performance. To reach this level, your design tools must be flexible enough to accommodate your creativity, but also robust enough to cope with the complexity inherent in today’s products. With the right 3D CAD software, you can view the finished product at any time and spot manufacturing issues that you might not have seen before production with a 2D drawing.

Most design processes start with a general idea. You therefore need a solution that has all the functionalities required to manage this first phase. The SOLIDWORKS user interface is intuitive and easy to use. This allows you to focus on your designs rather than using the software.

SOLIDWORKS also increases your productivity with SmartMates. Smart components and smart fasteners anticipate how the components should be put together. Other innovative features such as Generative Design allow you to define design criteria so that the software can automatically create the geometry.

SOLIDWORKS gets your products into production quickly and easily. The associativity of SOLIDWORKS allows you to relate a 2D drawing directly to a solid 3D model. This way, updates made in the 3D model are automatically reflected in all views of the 2D drawing.

If you find creating 2D drawings cumbersome or time consuming, SOLIDWORKS MBD allows you to link your 2D drawing to the 3D model. The design experience is more precise and interactive: any changes you make to your design are automatically applied in both versions.

Up to the production stage, transfers between stakeholders must be simple. A good way to set yourself apart may be to add “smart” components to your products. The link between engineers in the mechanical field and in the electrical field is the pivotal point in product development. With SOLIDWORKS software, you synchronize electrical and mechanical designs with bidirectional links, optimize cable routing for precise assembly, and more.

The last step is sharing these files with customers, partners and production. With SOLIDWORKS, you can send interactive files in a variety of formats, so everyone can see what you send. You can save dimensions, tolerances and 3D scores in a variety of formats. Unlike 2D drawings, your customers can take measurements, view exploded views and section views, and also highlight and rotate dimensions.

With a 3D CAD system, all design changes are automatically updated on all associated components, including drawings, NC tool paths, and required tooling. It also allows technical communications and manufacturing planning to be synchronized with the latest version of the design.

Find out how SOLIDWORKS solutions can help you bridge the gap between design and manufacture by visiting the site

http://www.SOLIDWORKS.FR/SW2018_IDM