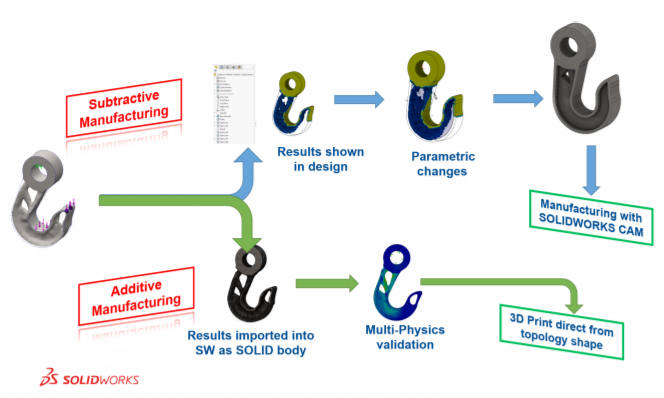

Topology study in SOLIDWORKS Simulation 2019 allows you to explore design iterations of a component that meet a given optimization goal (environment and manufacturing techniques) and imposed geometric limits (available in SOLIDWORKS Simulation Professional and SOLIDWORKS Simulation Premium).

The ability to generate an optimized shape will help you create an innovative design by meeting performance and manufacturing challenges. By delivering a model early in the process, topology optimization tools will allow you to have a collaborative approach to design and manufacturing with the goal of becoming very competitive in the market.

What topology optimization does for you:

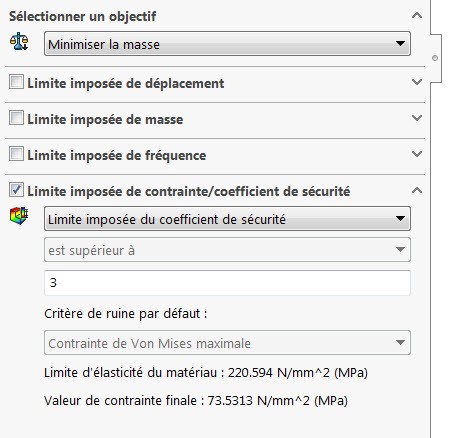

In SOLIDWORKS Simulation 2019, the topology study includes new stress values (safety factor) and of frequency as imposed design limits.

To specify an enforced frequency limit, in the Property Manager – Objectives and Enforced Limits, select Enforced Frequency Limit. Enter an upper or lower frequency limit, or an acceptable frequency range for the selected modal shapes

Note: Run a frequency study with the original model (maximum design space), before running a topology study with imposed frequency limits, to assess the range of acceptable natural frequencies.

Select Modal tracking to instruct the optimization solver to follow the order of selected modal deformations derived from the initial geometry (through optimization iterations) when you apply frequency imposed limits.

When the option Modal tracking is unchecked, the solver follows the current order of the modal deformations as derived for each optimization iteration. This is for example the case for an optimization objective aiming at a reduction of 50% of the mass and an imposed limit of frequency on the first modal deformation. The first modal deformation of the initial geometry becomes the second or third modal deformation of the optimized geometry.

For example, you can run a topology study to find the optimum shape of a model with the greatest stiffness for a 50% weight reduction and a maximum acceptable stress condition. A constrained stress limit applies the condition that a model after optimization cannot experience stresses greater than a percentage factor of the yield strength of the material.

To specify a constraint imposed limit, in the Property Manager – Objectives and Enforced Limits, select Imposed stress limit / safety coefficient.

For the Type, select either Constraint imposed limit, that is Imposed limit of the safety coefficient.

In summary, topology optimization can bring you several benefits and give you the competitive edge in a very competitive market.

To learn more about the topology optimization capabilities of SOLIDWORKS and how it could improve your design and manufacturing process, please visit https://www.pbicadcam.com/blogue or call us at (450) 449-2525.