Autodesk offers several modeling software solutions, the most popular being AutoCAD. It is the design software of choice for architects, engineers, and construction professionals. Although AutoCAD lets you create 3D models using solids, surfaces, and mesh objects, it is much more advanced in terms of its 2D capabilities. Nonetheless, Autodesk offers other solutions fully geared towards 3D applications, such as Netfabb, Fusion 360 or TinkerCAD. While Fusion 360 offers complete CAD (Computer Aided Design), CAM (Computer Aided Manufacturing) and CAE (Computer Aided Engineering) tools, Netfabb was developed specifically for additive manufacturing, design and simulation to streamline workflows and Reduce design errors prior to manufacture. Originally developed by the German company netfabb GmbH, it was acquired by Autodesk in 2015.

Netfabb’s main features include converting and importing models from various CAD applications, creating models that take advantage of AM, and maximizing the number of parts that fit in each build. So it is one 3D printing software that seamlessly transitions from design to manufacturing. Most functions fall into four categories: the first is build preparation, the second is design optimization for additive manufacturing, the third is machine integration, and the last is simulation. For those who are already designing 3D parts with Fusion 360, using Netfabb’s capabilities is fairly easy as Fusion 360 supports direct connection. You can easily download it from the Fusion 360 add-in menu.

Netfabb is 3D printing software designed to seamlessly transition from design to manufacturing

Netfabb: The software to prepare for additive manufacturing

Converting a 3D model into a 3D printed part involves more steps than meets the eye, which is why Netfabb software exists. The main purpose of the software is to prepare three-dimensional files for printing by converting them into 2.5-dimensional slice files, which consist of a list of two-dimensional layers that the 3D printer creates over time.

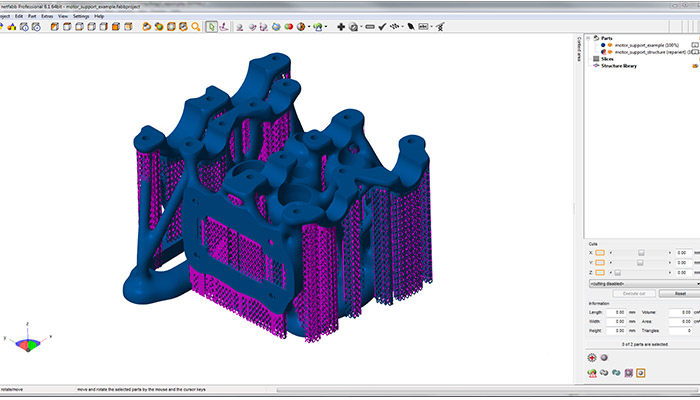

Many additional functions have been built in to help professional users prepare for printing. The simplest functions revolve around the construction preparation such as importing, analyzing and repairing CAD models imported into the software. But also modifying models for production by adjusting wall thickness, smoothing out rough areas, and using semi-automated tools that recognize where you need support. You can also convert Netfabb to CAD, use advanced toolpaths to achieve maximum surface quality, part density and speed, and finally algorithms allow you to place parts optimally within the build volume.

Netfabb provides design optimization tools that you can apply to your 3D models

Given the design freedom afforded by additive manufacturing technologies, it makes sense that Netfabb would provide design optimization tools that you can apply to your 3D models. These are part of the second family of features: Design Optimization for Additive Manufacturing, and include internal lattice structures, topology optimization, integrated performance analysis, and optimization engine to meet stress requirements and reduce weight.

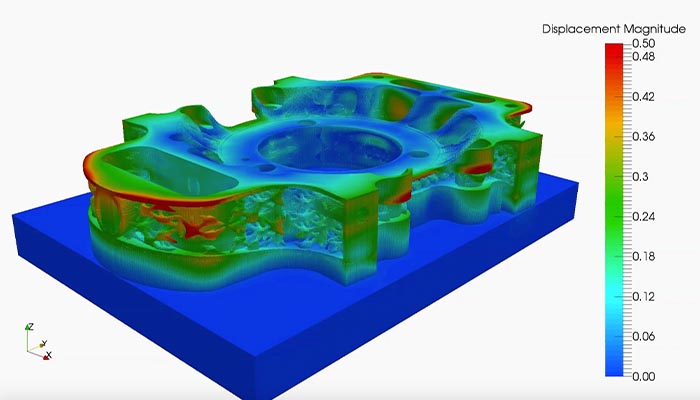

Finally, simulation is also an important feature of this software. For example, Netfabb’s simulation capabilities allow you to predict the thermo-mechanical behavior of additively manufactured parts during selective laser sintering and Direct Energy Deposition (DED) manufacturing processes. The goal is to reduce 3D printing errors as much as possible by predicting how the parts might be affected by sensitive manufacturing processes like those for metal parts.

Netfabb’s simulation capabilities are quite advanced | Image via Autodesk

Netfabb is available in Standard, Premium, Ultimate and Simulation versions. The pricing plan depends on which version you go for, but to give you an idea, a 1-year license costs $240 for the standard plan (includes only the basic pre-build features), while the same for the premium Version costs $4,450. Pricing for the Ultimate and Simulation versions are not listed on the website, you must contact Autodesk directly. More information about the full range of functions of the two versions can be found HERE.

*Cover image via Autodesk

What do you think of Netfabb? Leave us a comment or share it with us on Facebook, Twitter, LinkedIN or Xing. Would you also like to receive a summary of the most important news in 3D printing and additive manufacturing directly and conveniently in your mailbox? Then register now for our weekly newsletter.